Sometimes I need to release materials internally for testing. Do I need to create a work order to release any material even internally? how can I manage all internal requisitions for material?

Thanks

Hi Fernando,

You could have users request parts via the ‘part request’ feature. They can go to production>part>part request and select ‘create part request(without order)’.

This will then notifier the warehouse picker to pick those parts for them/adjust them out of inventory for internal purposes. this way, you don’t have to create a work order.

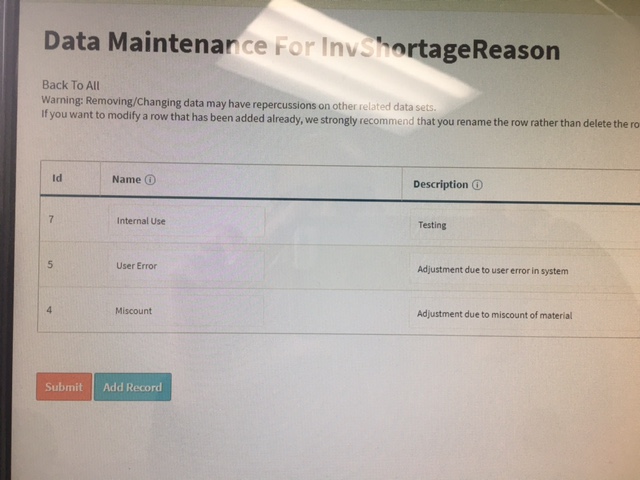

You can create a reason code titled ‘internal use’ or somehting along those lines in the data maintenance table titled invshortagereason (admin>maintenance>data maintenance>invshortagereason) AND you can specify the default warehouse picker (the one who gets the notification of the part request) with this config: default_wh_picker_id (admin>config settings>config settings).

Not that config requires the user id, not the user name. You’ll see the user IDs next to the user names in the user list (admin>users>users).

I hope this helps!

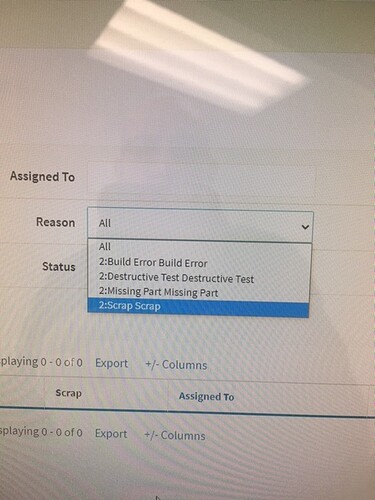

Thanks for your assistance, but somehow the reasons listed in Production > Part > Part Requests don’t match at all with Admin > Maintenance > Data Maintenance > Invshortagereason.

Please see the attached pictures.

Also, please confirm Production > Part > Part Requests > Status - Status for what? how can I add or modified Status in our Data maintenance?

Thanks

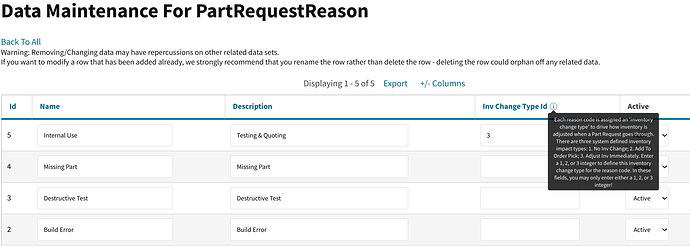

Apologies, the part request reasons are found at admin>maintenance>data maintenance>PartRequestReason

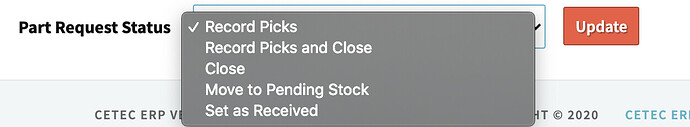

The status is set at the bottom of the page on the actual part request record, depending on the state of the request.

How do I close the part request? still the part is in my inventory

How do I discount from my inventory the quantity released for internal use?

Please provide full detail to do so.

Thanks

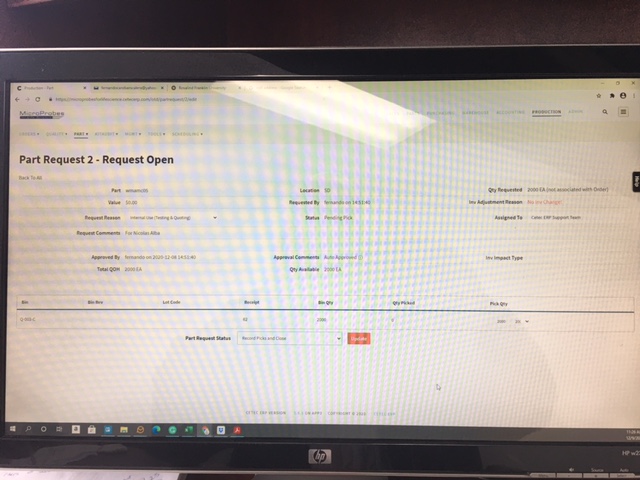

If you record the “pick” of the qty you want to adjust (at the bottom of the part request screen), and then set the part request to “record picks and close”, that will adjust down your inventory by that quantity. Make sure you have the proper inventory adjustment reason code set at the top of the part request screen.

Thanks

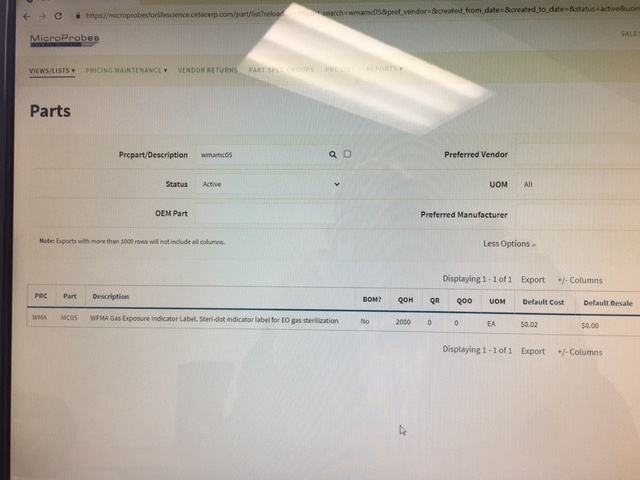

I just did that, refreshed my computer, and still, the quantity on hand of the item didn’t change.

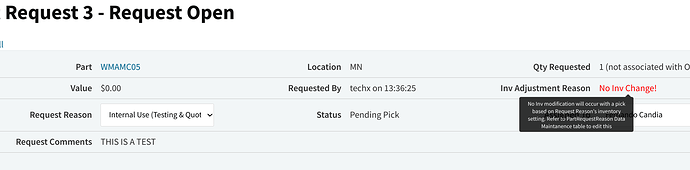

That is because you are selecting a PartRequestReason that is set to “No Inventory Change”.

I have gone into your PartRequestReason table (______________.cetecerp.com/tablemaint/PartRequestReason/edit?must_update=0)

and set the “Inv Change Type ID” to ‘3’

Now, if you load a test part request here, you’ll see an inventory adjustment reason code on the top right of the screen.

https://______________.cetecerp.com/otd/partrequest/3/edit

I’ve assigned that test part request for Qty 1 to your username in Cetec. You should be able to proceed and pick and close the part request (per the instructions in my previous post) and it should adjust the inventory now.

Thanks

Thanks for your detailed email.

How can I return released inventory back into the inventory?

Best,

@fernandocandia - you should always have the option to “unpick” the inventory from either an order or a part request.

Simply edit the Qty back down to zero on the pick, and click update.

The parts I am trying to return back to my inventory were picked, released, shipped and invoiced.

How can I return some of those pieces back to my inventory?

Thanks

Ah. You would want to locate the invoice number they shipped out on first. Look up that invoice, then on the left side-nav menu, you’ll see an option to “create RMA”.

Create an RMA, then specify which pieces you’re wanting to return on the RMA lines (and what quantities), then create a receiving PO against the RMA (there is a “create receiving PO” button).

And receive the pieces back into stock against that RMA PO. That is the proper process.

Alternatively, you could just do an inventory adjustment or a non-PO receipt (inventory adjustment upward from zero) if you wanted. The RMA process provides better traceability obviously.

Here is some RMA documentation that might be helpful for you - http://cetecerp.com/support/how-to/rma.html