Dear Support Team,

I hope this message finds you well.

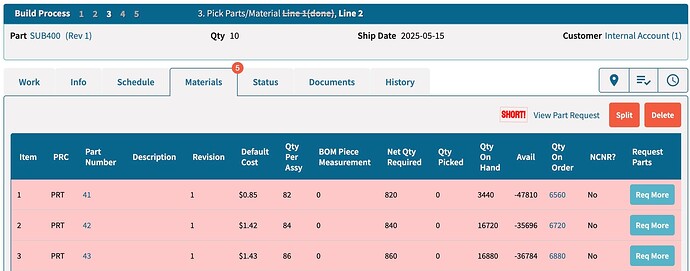

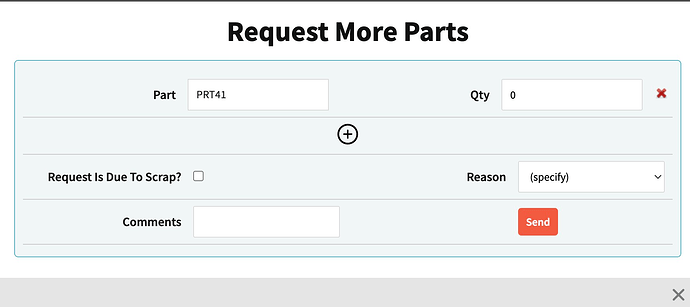

We currently use the scrap adder functionality to account for potential spillage of small SMT parts. Parts are picked based on the total required quantity plus the scrap adder. However, there are occasions where we need to adjust the scrap adder based on the actual quantities used during production.

Currently, once the parts are picked, the related line becomes grayed out in BOM Management. As a result, we have to follow a multi-step process to make adjustments:

- Unpick the parts in the Pick Part window

- update the pick part window to reflect the changes

- Adjust the scrap adder in BOM Management

- Update the BOM Management window to reflect the changes

- Re-update the Pick Part window to reflect the revised quantities

- Pick the parts again

- Perform a final update in Pick Parts window

This process is quite time-consuming. Could you please advise if there is a more streamlined method for handling this process?

Additionally, is it possible to enable editing of the scrap adder in BOM Management even after the parts have been picked? Allowing this flexibility would significantly enhance efficiency and ease of use when managing production changes.

Thank you as always for your continued support. I look forward to your guidance.

Best regards,

Mahtab