When performing a split, is there a way to not have the system split an item that physically cannot be split? Does it have to be marked in our back/admin end, like “Dont split something marked as EA”? Or is this a known issue type thing?

Example:

If something goes wrong in the build process, i split the WO so I can close out the good ones and keep working on the others. If the pick list isnt fully complete, or if we picked from two different lots, when I do a split we end up with half a unit. Or if I dropped a screw and had to use an extra one, now its an odd number and it splits that in half.

TIA

Hi,

Thanks for checking in. Let me get some more details from you so I can get a clearer picture of what’s going on. I just did some testing and didn’t run into the same issue, so I want to make sure I understand what we’re both seeing. To reproduce your case as closely as possible, I made sure to pick from different bins and in odd numbered quantities.

Just to check, when you’re splitting the line, are you clicking the “Scale to Pick” button? That is intended for when you have parts picked and a ship quantity set. It is meant to accurately scale the quantities for you.

Here are the recommended steps: Order Processing in Cetec ERP - How to Split a Line - YouTube

Is this similar to the process you’re using? If so, and if you’re still seeing issues, would you be able to send me a link to the order or orders where you’re seeing the splitting issues?

Thank you!

“have parts picked and a ship quantity set” - Could you elaborate on ‘ship quantity set’? Unsure what that means, thx.

I do the process as in the video, so thats consistent.

I just manually fixed the WOs that prompted this, so i dont have that to rely on.

In your testing, if you had a WO that had two units, and you had picked 37 screws (you used 18 on one, and 19 on the other because you dropped one and lost it), and then you did a split and scale to pick, how did it rectify that?

If you had two units, the first used one Thingymaboby from Lot 1, and the second used one Thingymaboby from Lot 2, and then split/scaled, how does it break it down for you? for me, it would put 0.5 Thingymaboby from Lot 1 and 0.5 Thingymaboby from Lot 2 on each of the new lines.

Well, I definitely let this one slip through the cracks! I truly apologize. Did you already repost about this and get this answered, or is this still awaiting a response?

My apologies again,

Cetec ERP Support

i think this is still up in the air, thx for checking in!

Sure. Thanks for your patience. Let me look at this again and refresh my memory.

Hi,

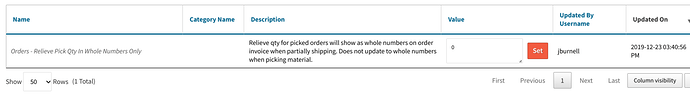

I consulted with our team, and there is a config setting to ensure you are only seeing whole numbers of parts after splitting an order. Go to Admin > Config Settings > Config Settings. Search for “whole.” You’ll find the configuration setting “Orders - Relieve Pick Qty in Whole Numbers Only.” Set the value to 1 and click Set.

Let us know if you need further help here, and again, thank you for your patience!

Cetec ERP Support

thank you!

I dont have admin rights, but my peeps that do said that searching for “whole” isnt coming up with anything. They are still looking for the setting you specified, but wanted to let me know about that speedbump.

Hi, we cant find that setting. Plz advise.

Hi,

It could be one of those pesky settings that is only accessible on my end, or after a certain action is taken in the system. I am able to see it on my end. Would you like me to turn it on for you?

Cetec ERP Support

yes please!

@Dellis